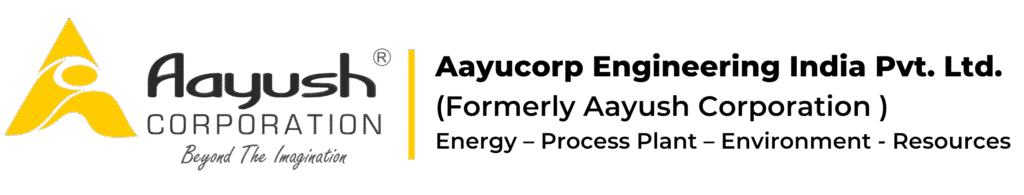

Fabrication Skid Product

Our Chemical Dosing Skids are precision-engineered systems designed for accurate and reliable chemical dosing across diverse industrial applications. These compact, skid-mounted units feature chemical storage tanks, metering pumps, flow control systems, and safety devices. Tailored to meet specific process requirements, they ensure efficient dosing, minimal wastage, and optimal system performance.

Key Features:

- Quality Standards: Each skid undergoes rigorous testing and inspection, ensuring compliance with industry standards and delivering exceptional performance and reliability.

- On-Time Delivery: A streamlined production process with advanced project tracking systems ensures prompt delivery without compromising on quality.

- Specialized Manufacturing: We employ state-of-the-art fabrication techniques, including precision welding and modular assembly, to meet exacting specifications.

- Site Support: Our expert team provides seamless commissioning and installation support to ensure smooth integration into your operations.

- Customer Relationships: We prioritize customer satisfaction through transparent communication, prompt after-sales support, and long-term partnerships.

The Chemical Injection Skids are advanced systems designed for precise chemical delivery to critical process points. Equipped with high-performance metering pumps, pressure relief valves, and control panels, they ensure accuracy and reliability under various operating conditions.

Why Choose Us:

- Quality Standards: Skids are subjected to detailed inspection practices, ensuring adherence to the highest engineering standards.

- On-Time Delivery: Comprehensive project management and streamlined workflows guarantee timely delivery.

- Specialized Manufacturing: Custom-designed for challenging environments, our skids are fabricated using cutting-edge materials and techniques.

- Site Support: Our commissioning and installation services ensure hassle-free integration with your processes.

- Customer Relationships: We focus on creating value through tailored solutions and exceptional client support.

Our Lube Oil Skids are compact, high-quality systems designed to enhance equipment performance by delivering consistent lubrication. Each skid integrates storage tanks, pumps, filters, and heat exchangers for optimized functionality.

Excellence in Fabrication:

- Quality Standards: Strict quality control measures and inspections ensure the durability and performance of every component.

- On-Time Delivery: Advanced scheduling and supply chain management help us meet tight deadlines effectively.

- Specialized Manufacturing: Innovative fabrication methods ensure a perfect fit for critical industrial applications.

- Site Support: Comprehensive commissioning and installation assistance for smooth operation from day one.

- Customer Relationships: Dedicated account managers and a responsive service team are always at your side.

Our Clean-In-Place (CIP) Skid Systems are custom-engineered to meet stringent cleaning requirements in process plants. These systems effectively clean piping, tanks, mixers, and other sanitary equipment without disassembly, minimizing downtime and maintaining hygiene standards.

Our Commitment:

- Quality Standards: Every skid undergoes robust inspection and testing to ensure compliance with regulatory requirements.

- On-Time Delivery: Efficient production processes and supply chain integration guarantee timely project completion.

- Specialized Manufacturing: From single tank to multi-tank configurations, our skids are built using advanced automation technologies.

- Site Support: We offer full commissioning, installation, and integration support, ensuring a seamless start-up.

- Customer Relationships: We build trust through ongoing support, proactive communication, and solutions tailored to your evolving needs.

Our Chemical Dosing Skids are precision-engineered systems designed for accurate and reliable chemical dosing across diverse industrial applications. These compact, skid-mounted units feature chemical storage tanks, metering pumps, flow control systems, and safety devices. Tailored to meet specific process requirements, they ensure efficient dosing, minimal wastage, and optimal system performance.

Key Features:

- Quality Standards: Each skid undergoes rigorous testing and inspection, ensuring compliance with industry standards and delivering exceptional performance and reliability.

- On-Time Delivery: A streamlined production process with advanced project tracking systems ensures prompt delivery without compromising on quality.

- Specialized Manufacturing: We employ state-of-the-art fabrication techniques, including precision welding and modular assembly, to meet exacting specifications.

- Site Support: Our expert team provides seamless commissioning and installation support to ensure smooth integration into your operations.

- Customer Relationships: We prioritize customer satisfaction through transparent communication, prompt after-sales support, and long-term partnerships.

The Chemical Injection Skids are advanced systems designed for precise chemical delivery to critical process points. Equipped with high-performance metering pumps, pressure relief valves, and control panels, they ensure accuracy and reliability under various operating conditions.

Why Choose Us:

- Quality Standards: Skids are subjected to detailed inspection practices, ensuring adherence to the highest engineering standards.

- On-Time Delivery: Comprehensive project management and streamlined workflows guarantee timely delivery.

- Specialized Manufacturing: Custom-designed for challenging environments, our skids are fabricated using cutting-edge materials and techniques.

- Site Support: Our commissioning and installation services ensure hassle-free integration with your processes.

- Customer Relationships: We focus on creating value through tailored solutions and exceptional client support.

Our Lube Oil Skids are compact, high-quality systems designed to enhance equipment performance by delivering consistent lubrication. Each skid integrates storage tanks, pumps, filters, and heat exchangers for optimized functionality.

Excellence in Fabrication:

- Quality Standards: Strict quality control measures and inspections ensure the durability and performance of every component.

- On-Time Delivery: Advanced scheduling and supply chain management help us meet tight deadlines effectively.

- Specialized Manufacturing: Innovative fabrication methods ensure a perfect fit for critical industrial applications.

- Site Support: Comprehensive commissioning and installation assistance for smooth operation from day one.

- Customer Relationships: Dedicated account managers and a responsive service team are always at your side.

Our Clean-In-Place (CIP) Skid Systems are custom-engineered to meet stringent cleaning requirements in process plants. These systems effectively clean piping, tanks, mixers, and other sanitary equipment without disassembly, minimizing downtime and maintaining hygiene standards.

Our Commitment:

- Quality Standards: Every skid undergoes robust inspection and testing to ensure compliance with regulatory requirements.

- On-Time Delivery: Efficient production processes and supply chain integration guarantee timely project completion.

- Specialized Manufacturing: From single tank to multi-tank configurations, our skids are built using advanced automation technologies.

- Site Support: We offer full commissioning, installation, and integration support, ensuring a seamless start-up.

- Customer Relationships: We build trust through ongoing support, proactive communication, and solutions tailored to your evolving needs.

Chemical Dosing Skid

Our Chemical Dosing Skids are precision-engineered systems designed for accurate and reliable chemical dosing across diverse industrial applications. These compact, skid-mounted units feature chemical storage tanks, metering pumps, flow control systems, and safety devices. Tailored to meet specific process requirements, they ensure efficient dosing, minimal wastage, and optimal system performance. Key Features:- Quality Standards: Each skid undergoes rigorous testing and inspection, ensuring compliance with industry standards and delivering exceptional performance and reliability.

- On-Time Delivery: A streamlined production process with advanced project tracking systems ensures prompt delivery without compromising on quality.

- Specialized Manufacturing: We employ state-of-the-art fabrication techniques, including precision welding and modular assembly, to meet exacting specifications.

- Site Support: Our expert team provides seamless commissioning and installation support to ensure smooth integration into your operations.

- Customer Relationships: We prioritize customer satisfaction through transparent communication, prompt after-sales support, and long-term partnerships.

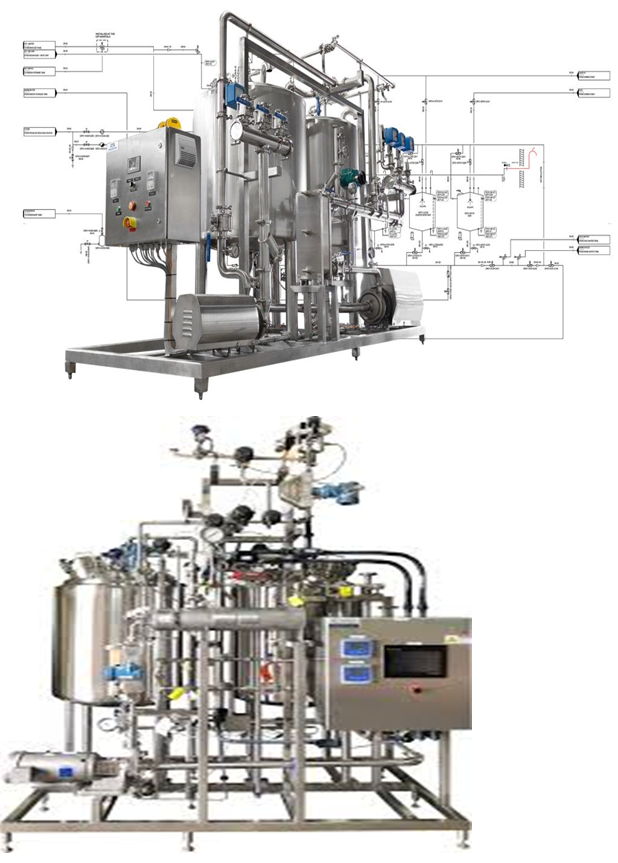

Chemical Injection Skid

The Chemical Injection Skids are advanced systems designed for precise chemical delivery to critical process points. Equipped with high-performance metering pumps, pressure relief valves, and control panels, they ensure accuracy and reliability under various operating conditions. Why Choose Us:- Quality Standards: Skids are subjected to detailed inspection practices, ensuring adherence to the highest engineering standards.

- On-Time Delivery: Comprehensive project management and streamlined workflows guarantee timely delivery.

- Specialized Manufacturing: Custom-designed for challenging environments, our skids are fabricated using cutting-edge materials and techniques.

- Site Support: Our commissioning and installation services ensure hassle-free integration with your processes.

- Customer Relationships: We focus on creating value through tailored solutions and exceptional client support.

Lube Oil Skid

Our Lube Oil Skids are compact, high-quality systems designed to enhance equipment performance by delivering consistent lubrication. Each skid integrates storage tanks, pumps, filters, and heat exchangers for optimized functionality. Excellence in Fabrication:- Quality Standards: Strict quality control measures and inspections ensure the durability and performance of every component.

- On-Time Delivery: Advanced scheduling and supply chain management help us meet tight deadlines effectively.

- Specialized Manufacturing: Innovative fabrication methods ensure a perfect fit for critical industrial applications.

- Site Support: Comprehensive commissioning and installation assistance for smooth operation from day one.

- Customer Relationships: Dedicated account managers and a responsive service team are always at your side.

Clean-In-Place (CIP) Skid

Our Clean-In-Place (CIP) Skid Systems are custom-engineered to meet stringent cleaning requirements in process plants. These systems effectively clean piping, tanks, mixers, and other sanitary equipment without disassembly, minimizing downtime and maintaining hygiene standards. Our Commitment:- Quality Standards: Every skid undergoes robust inspection and testing to ensure compliance with regulatory requirements.

- On-Time Delivery: Efficient production processes and supply chain integration guarantee timely project completion.

- Specialized Manufacturing: From single tank to multi-tank configurations, our skids are built using advanced automation technologies.

- Site Support: We offer full commissioning, installation, and integration support, ensuring a seamless start-up.

- Customer Relationships: We build trust through ongoing support, proactive communication, and solutions tailored to your evolving needs.