Erection & Commissioning Services

At Aayush Corporation, we offer end-to-end Erection & Commissioning Services tailored to meet the unique needs of various industrial sectors. Our expertise spans multiple engineering domains, ensuring seamless project execution, system integration, and operational readiness. With a dedicated team and robust technical capabilities, we ensure that every project is executed efficiently, safely, and within the stipulated timeframe.

Our Services Include

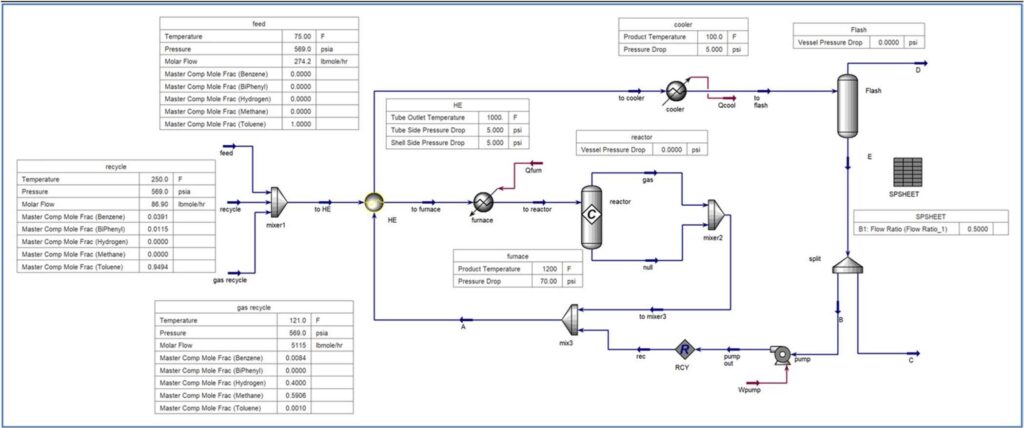

Process Engineering

- Installation and setup of process equipment such as distillation columns, heat exchangers, and pressure vessels.

- Calibration and testing of systems to achieve desired heat and mass balance.

- Alignment and commissioning of critical utilities like boilers, cooling towers, and storage tanks.

- Performance validation through rigorous testing and troubleshooting.

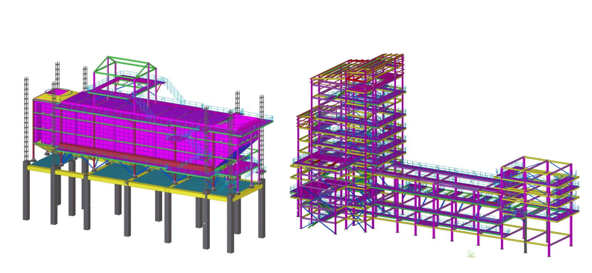

Civil & Structural Engineering

- Erection of support structures for equipment across power, steel, sugar, and cogeneration plants.

- Construction and installation of RCC and steel structures, including silos, hoppers, and storage tanks.

- Alignment and installation of pipe racks, duct supports and retaining walls.

- Structural inspections to ensure safety and compliance with industry standards.

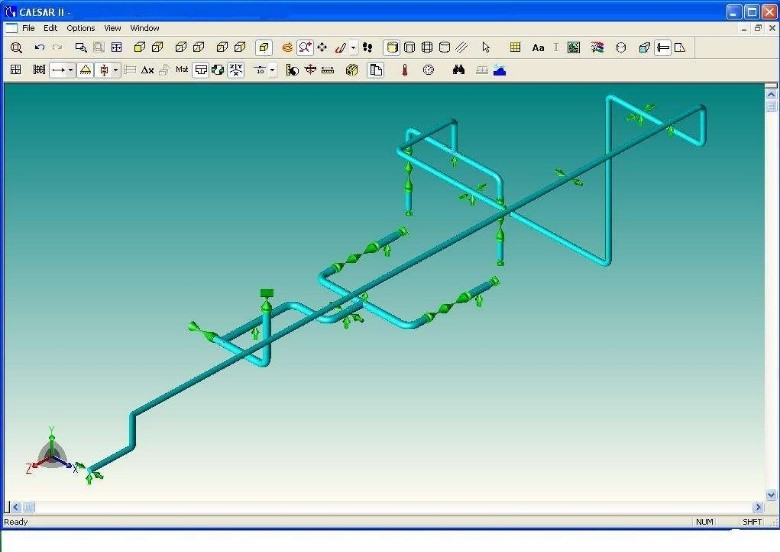

Piping Engineering

- Installation of pipelines, including utility lines, steam lines, and process pipelines, adhering to ASME, API, and other applicable standards.

- Alignment and testing of pipe racks, supports, and expansion joints.

- Isometric piping erection and hydro-testing to ensure leak-proof systems.

- Flexibility analysis and final adjustments for high-pressure and temperature pipelines.

Electrical & Instrumentation Engineering

- Installation of power distribution systems, transformers, and switchgear.

- Cabling and termination for control panels and field instruments.

- Calibration and testing of instruments like pressure transmitters, flow meters, and temperature sensors.

- Loop checking and system integration to ensure seamless operation.

- Commissioning of control systems, including PLC, DCS, and SCADA.

Process Engineering

- Installation and setup of process equipment such as distillation columns, heat exchangers, and pressure vessels.

- Calibration and testing of systems to achieve desired heat and mass balance.

- Alignment and commissioning of critical utilities like boilers, cooling towers, and storage tanks.

- Performance validation through rigorous testing and troubleshooting.

Civil & Structural Engineering

- Erection of support structures for equipment across power, steel, sugar, and cogeneration plants.

- Construction and installation of RCC and steel structures, including silos, hoppers, and storage tanks.

- Alignment and installation of pipe racks, duct supports and retaining walls.

- Structural inspections to ensure safety and compliance with industry standards.

Piping Engineering

- Installation of pipelines, including utility lines, steam lines, and process pipelines, adhering to ASME, API, and other applicable standards.

- Alignment and testing of pipe racks, supports, and expansion joints.

- Isometric piping erection and hydro-testing to ensure leak-proof systems.

- Flexibility analysis and final adjustments for high-pressure and temperature pipelines.

Electrical & Instrumentation Engineering

- Installation of power distribution systems, transformers, and switchgear.

- Cabling and termination for control panels and field instruments.

- Calibration and testing of instruments like pressure transmitters, flow meters, and temperature sensors.

- Loop checking and system integration to ensure seamless operation.

- Commissioning of control systems, including PLC, DCS, and SCADA.

Process Engineering

- Installation and setup of process equipment such as distillation columns, heat exchangers, and pressure vessels.

- Calibration and testing of systems to achieve desired heat and mass balance.

- Alignment and commissioning of critical utilities like boilers, cooling towers, and storage tanks.

- Performance validation through rigorous testing and troubleshooting.

Civil & Structural Engineering

- Erection of support structures for equipment across power, steel, sugar, and cogeneration plants.

- Construction and installation of RCC and steel structures, including silos, hoppers, and storage tanks.

- Alignment and installation of pipe racks, duct supports and retaining walls.

- Structural inspections to ensure safety and compliance with industry standards.

Piping Engineering

- Installation of pipelines, including utility lines, steam lines, and process pipelines, adhering to ASME, API, and other applicable standards.

- Alignment and testing of pipe racks, supports, and expansion joints.

- Isometric piping erection and hydro-testing to ensure leak-proof systems.

- Flexibility analysis and final adjustments for high-pressure and temperature pipelines.

Electrical & Instrumentation Engineering

- Installation of power distribution systems, transformers, and switchgear.

- Cabling and termination for control panels and field instruments.

- Calibration and testing of instruments like pressure transmitters, flow meters, and temperature sensors.

- Loop checking and system integration to ensure seamless operation.

- Commissioning of control systems, including PLC, DCS, and SCADA.